Welded Plate and Shell Heat Exchanger

Structure and Characteristics

The plate and shell heat exchanger adopts advantage of plate heat exchanger, meanwhile making up for shortcoming of shell and tube heat exchanger. The oval transfer plate combine with shell distribute the stress evenly to be more suitable for operation under changing temperature. At the same time, to provide compact size, high efficiency, and high temperature resistance and so on.

Plate Side Dismountable Type is common in application, following illustration will help your to better understand its structure.

Features

High Heat Transfer Efficiency

As it is fully welded and not use gasket, the available temperature is 600℃ (up to 900℃ ).

High Economical Efficiency

The compact size results to low cost, less installation area. And it does not need replacing gasket because of its fully welded type.

Application Range (Minimum, Max):

- Heat Transfer Area (m2) 0.3 1500

- Design Temperature (℃) -50 500

- Design Pressure (Bar) Full Vacuum 60

- Application Code ASME, KS, JIS, BS, PED, ML

- Plate Material SS304, SS316L, 254SMO Nickel Alloy, C-276 , Titanium

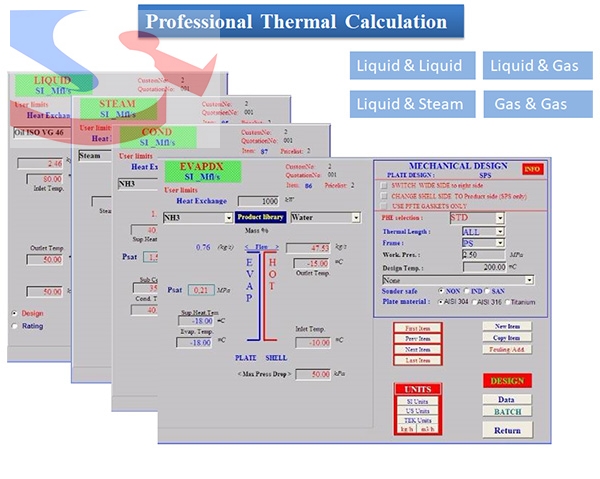

Thermal Calculation and Structure Design

Based on Expert engineer thermal calculation by profressional software, we will offer technical solution by thermal data sheet. Meanwhile, we will proposal the premium structure design for Plate and Shell Heat Exchanger.

Sorted Model Design for Shell Dismountable Plate Shell Heat Exchanger

Sorted Model Design for Shell Full Welded Plate Shell Heat Exchanger

Professional Manufacture Process for Plate and Shell Heat Exchanger

We apply for Automatic Plasma Welding Solution for Welded Plate Bundle

Plasma Welding Performance for Plate and Shell Heat Exchanger